Battery management

From cell sensing, cell connect, and cell contacting systems to temperature monitoring and voltage monitoring, we’re helping to shape the future of electric vehicles. We help customers design, produce, and optimize interconnect assemblies within today’s most advanced battery management systems. Our unique vertical integration provides the broadest range of material, fabrication, and assembly capabilities in the industry. Challenge us. Our experienced designers, engineers, and scientists will work with you to solve your toughest application needs.

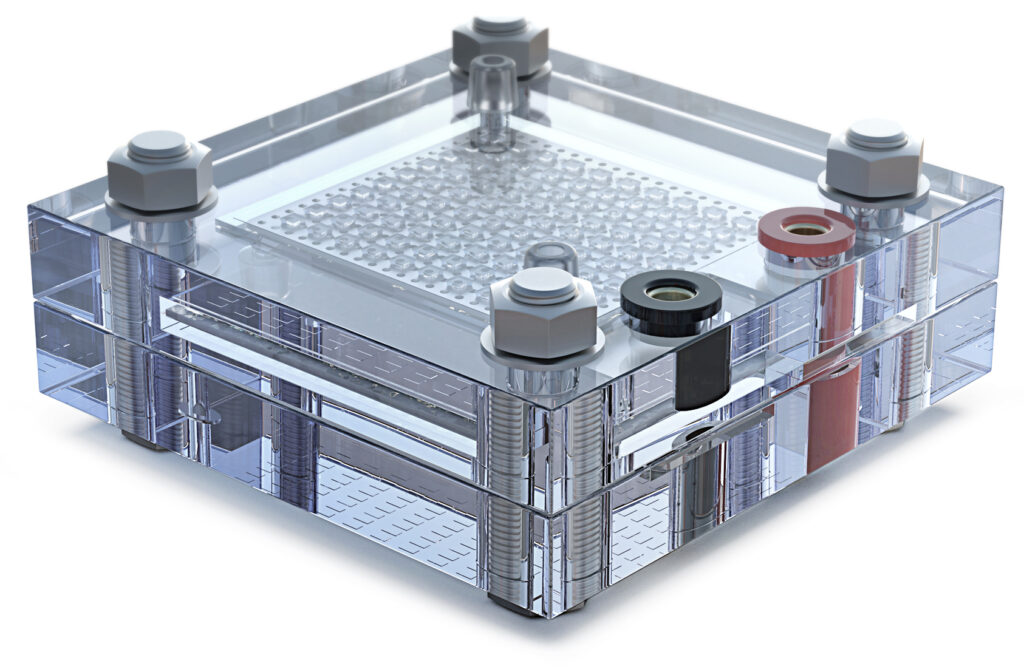

Smarter, more customized battery interconnects.

Innovative, reliable interconnect solutions within your battery management system are critical to monitoring the health, efficiency, and overall operational system of your EV battery. This requires flexible, intelligent harness technology that will stay interconnected to individual battery cells while adapting to expansion and contraction during charge and discharge cycles. Work with us. We’ll help customize a solution for your unique electrification needs.

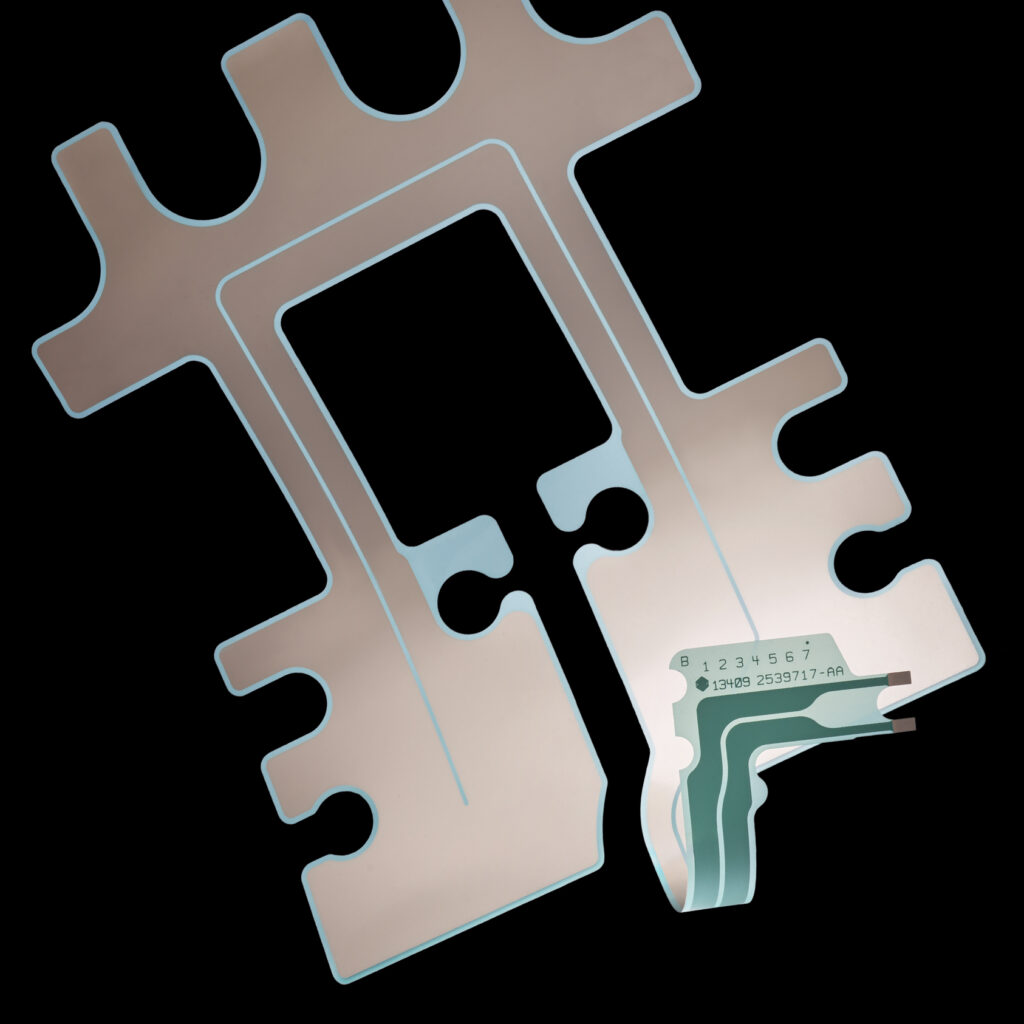

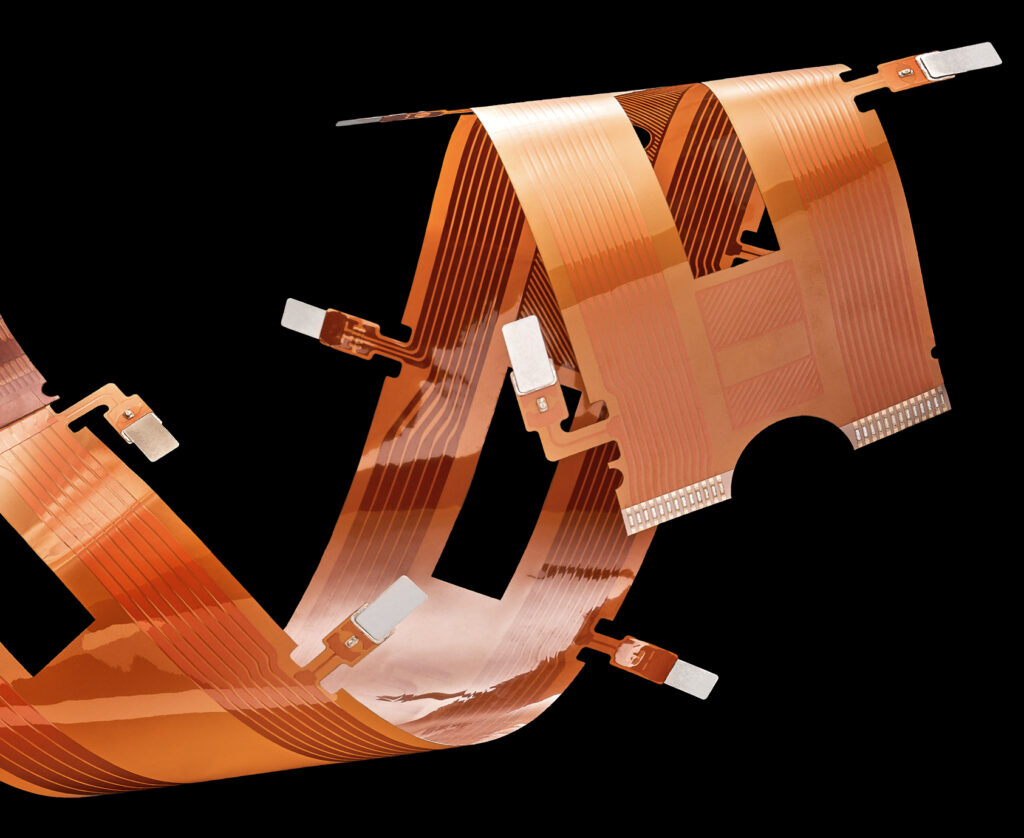

Flexible circuits, proven in the harshest automotive environments.

Our flexible printed circuits (FPCs) do more than conform to virtually any design need. They also offer decades of proven performance in extreme conditions. Our unique FPC technology can effectively link battery cells to vehicle electronics. The necessary electronic components can be surface mounted to the FPC, and the inherent flexibility allows for the battery pack’s expansion and contraction. It’s flexible technology that delivers space and weight savings that translate into improved miles per charge (MPC).

PROOF POINTS

Key collaborative relationships to develop battery solutions

Multiple products with decades of proven performance in harsh applications

PI, PET, and PEN circuitry

Adhesive and adhesives technology

Etched copper circuits ideal for low- to medium-voltage applications

Ultra-thin flexible and large format [24-inch wide by unlimited length (roll processing)]

Choice of base substrates to balance requirements against cost

Copper is lower cost than the traditional alloys used for flexible heaters

Also offer PTF or printed inks for stretchable and conforming solutions

PTC inks for self-regulation also available

Design, review, and assistance

- Key collaborative relationships to develop battery solutions

- Multiple products with decades of proven performance in harsh applications

- PI, PET, and PEN circuitry

- Adhesive and adhesives technology

- Etched copper circuits ideal for low- to medium-voltage applications

- Ultra-thin flexible and large format [24-inch wide by unlimited length (roll processing)]

- Choice of base substrates to balance requirements against cost

- Copper is lower cost than the traditional alloys used for flexible heaters

- T1186 (Also offer PTF or printed inks for stretchable and conforming solutions)

- PTC inks for self-regulation also available

- Design, review, and assistance

We’re here to help.

Connect with our engineers to find the right solution for any challenge.