WE ENABLE A MORE CONNECTED AND INNOVATIVE WORLD.

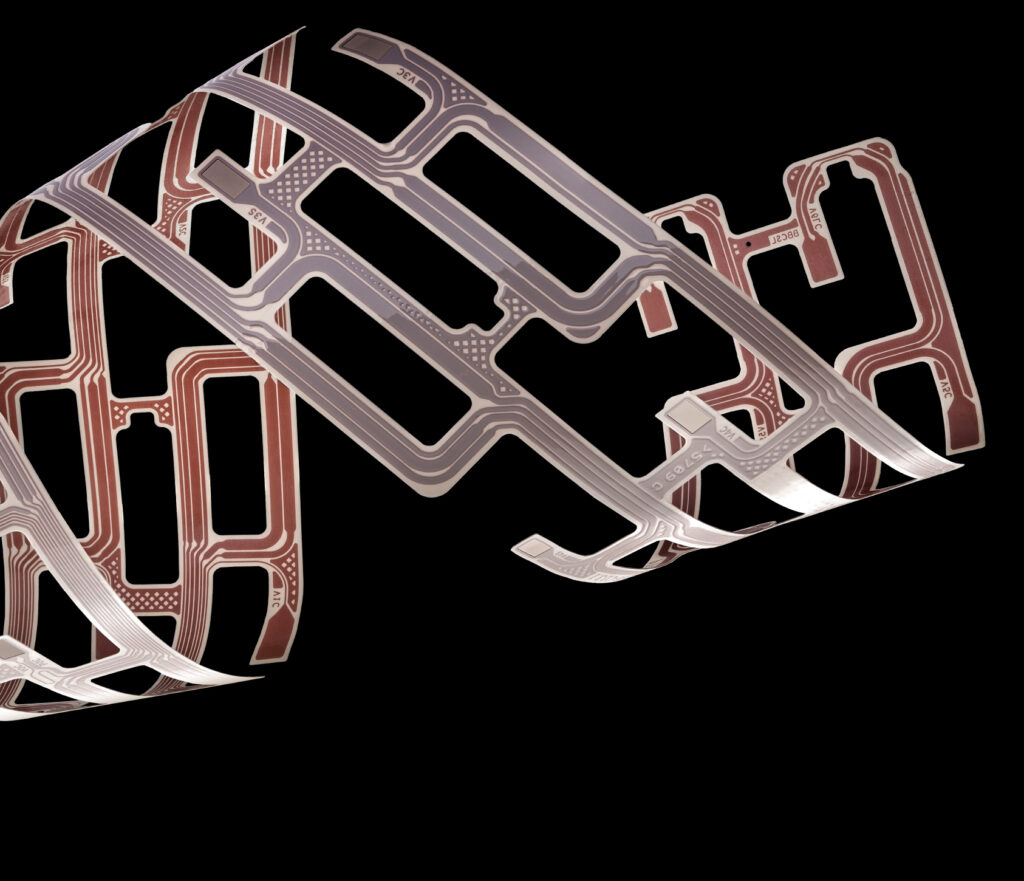

For more than 65 years, Sheldahl has designed and manufactured the custom materials and flexible printed circuits needed to help connect and power new possibilities. We do this by collaborating with our customers to develop new, flexible technologies that shape innovation to their unique applications – now and for the future.

Sheldahl

employees

800+

Facility square

footage

350K+

Miles of product

produced annually

25K+

Sheldahl’s designers and engineers work with customers to ideate, solve, and create.

We took part in NASA’s very first satellite program, all its manned space travel, and created materials on board the James Webb Space Telescope.

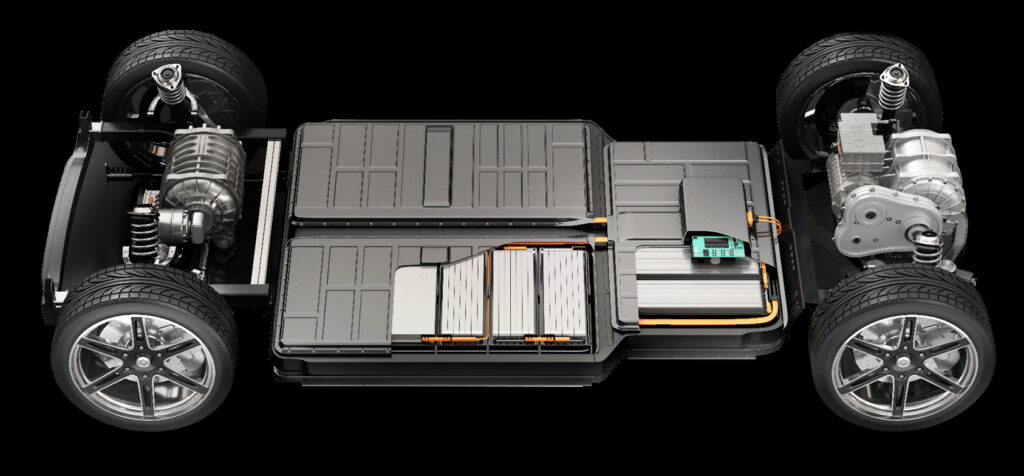

We helped engineer the first flexible automotive circuit and now work to enable more efficient electrification, improved battery management, and more reliable autonomous mobility.

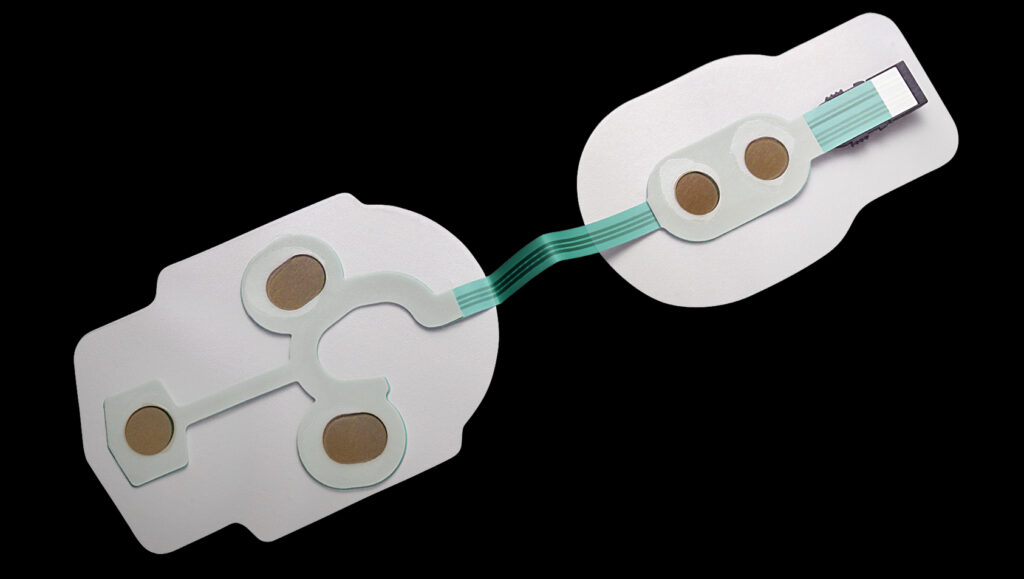

We help make remote monitoring wearables possible, bio-compatible machine interfaces friendlier, and medical devices more precise with the data connections needed for delicate surgery.

Capabilities

Capabilities that advance possibility.

From flexible printed circuits and electronics to thermal control materials and unidirectional tapes, our capabilities enable flexible innovation in a wide range of sectors and industries. Our strong, versatile, lightweight solutions offer durability and conformability, plus a higher-quality connectivity that will broaden your imagination to see beyond the limitations of today.

OUR CORE TECHNOLOGIES

- Flexible circuits

- Printed electronics

- Electronic materials

- Thermal control materials

- Unidirectional splicing tapes

OUR CORE PROCESSES

- Prototyping

- Roll-to-roll automated processing

- Printed polymer thin film

- Standard flexible circuitry (subtractive)

- Large-format screen printing (additive)

- Surface finishing

- Assembly

- Circuitry finishing

- Vacuum deposition

- Adhesive formulation, coating & laminating

- Perforating & embossing

- Slitting & sheeting

- Punching, patterning & forming

We’re here to help.

Connect with our engineers to find the right solution for any challenge.